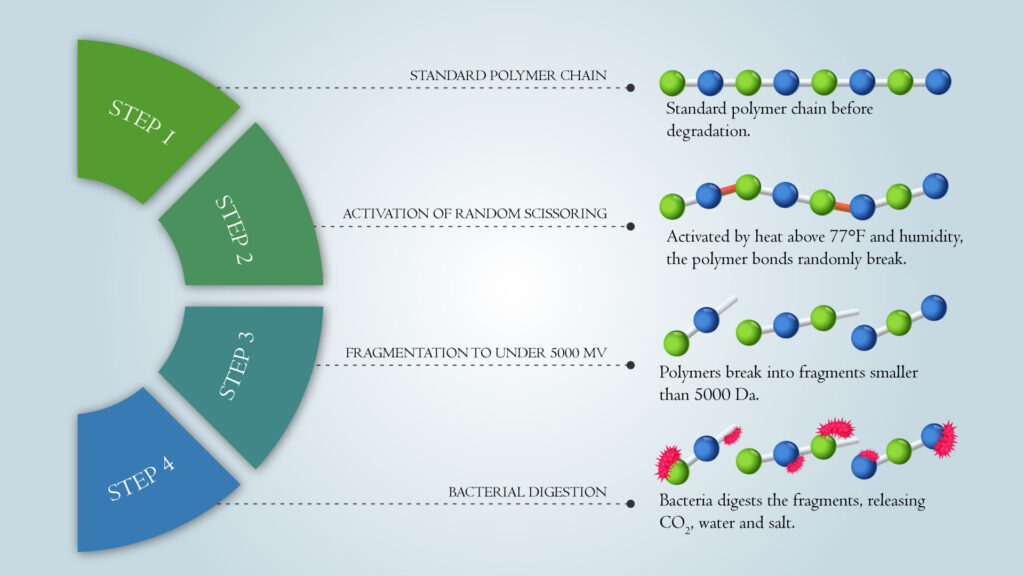

Chain scissoring refers to a chemical process in which the molecular chain of a polymer is broken, typically at the weakest link. This can happen through chemical reactions like oxidation or thermal degradation. The term is often used in the context of polymer degradation when chains of long molecular compounds are split into smaller fragments, leading to changes in the material’s properties, such as reduced strength or elasticity. Chain scissoring is relevant in understanding the durability and lifespan of various plastics and polymers.

Our Technology

RAWS Technology harnesses a groundbreaking process called “Thermal Random Assimilation” to break down polymers into their most basic components.

Unlike traditional methods that leave behind microplastics, RAWS utilizes low-temperature heat (above 25°C or 77°F) and surface humidity to activate a random scissoring mechanism within the polymer chains.

This process progressively fragments the plastic into smaller pieces until they reach a molecular weight under 5000 MW. At this stage, naturally occurring bacteria in the environment digest these fragments, converting them into harmless byproducts like carbon dioxide, water, and salt.

The result is an eco-friendly solution that avoids the accumulation of hazardous pollutants, oil residues, or methane gas.

RAWS represents a significant advancement in sustainable plastic depolymerization, offering an effective way to reduce the environmental impact of plastic waste.

How RAWS Technology Works